HIP’n GO

dual mobility cups

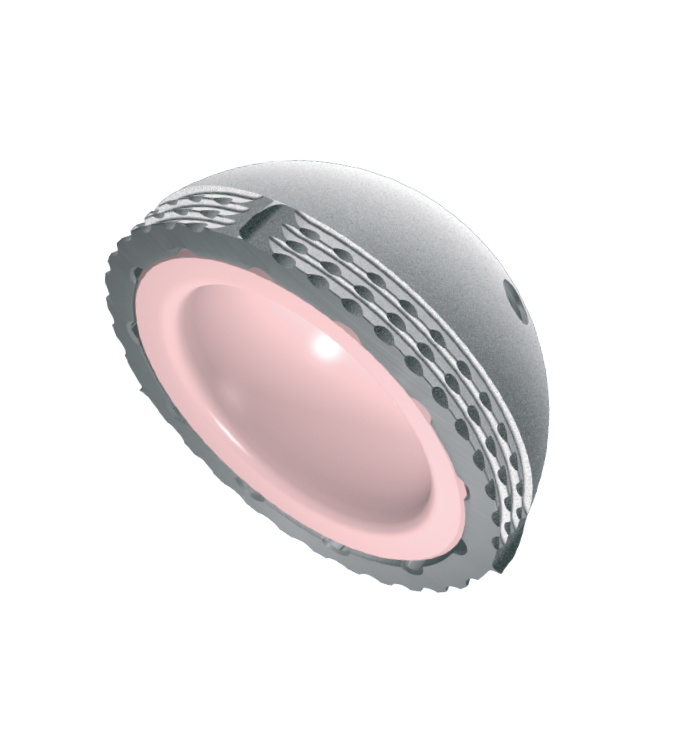

The primary stability of the Hip’n go cementless acetabular cup is achieved at the periphery by means of extra macrostructures (1 mm thickness) and 3 fins that block the implant in rotation. A double coating of porous titanium and hydroxyapatite provides secondary fixation, validated by over 15 years of clinical experience

The Hip’n go universal design allows the surgeon to choose between a dual mobility cup (press-fit, tripod or cemented) and a rigid cup (BIOLOX delta or UHMWPE liner) during the preoperative planning phase or during the procedure itself.

HIP’n GO

dual mobility cups

The primary stability of the Hip’n go cementless acetabular cup is achieved at the periphery by means of extra macrostructures (1 mm thickness) and 3 fins that block the implant in rotation. A double coating of porous titanium and hydroxyapatite provides secondary fixation, validated by over 15 years of clinical experience

The Hip’n go universal design allows the surgeon to choose between a dual mobility cup (press-fit, tripod or cemented) and a rigid cup (BIOLOX delta or UHMWPE liner) during the preoperative planning phase or during the procedure itself.

Product line

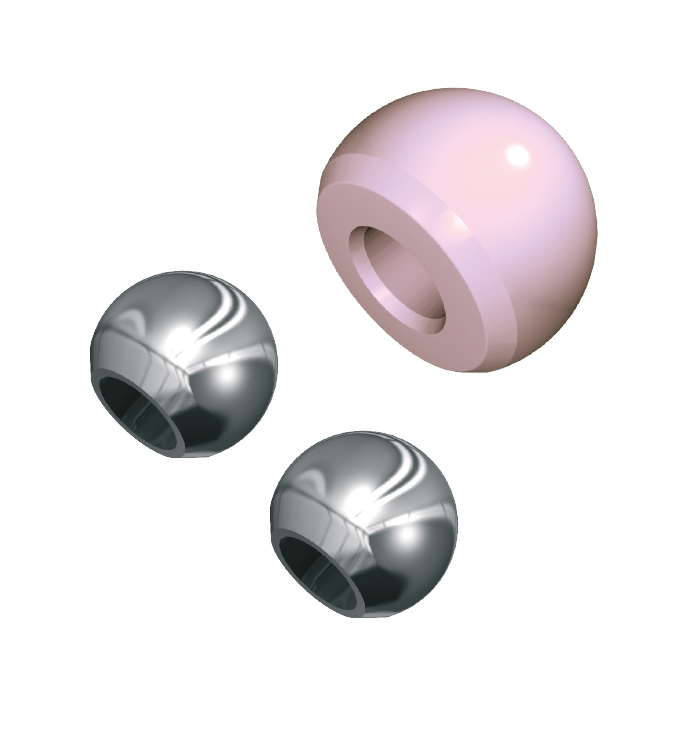

Hip’n go dual mobility cups are available in 10 sizes for each model (press-fit, tripod or cemented) ranging from 46 mm to 64 mm diameter in 2-mm increments.

The matching liners have an internal diameter of 22.2 mm for the size 46 cup and 28-mm for the 48 to 64 mm cups.

Features and materials

The metal-back shells are made of cobalt chrome (CoCr) and have a mirror polished inner surface.

The outer surface of the cemented dual mobility cups has a mirror finish and grooves for cement compression and binding.

The liners are made of UHMWPE (Ultra High Molecular Weight PolyEthylene).

Instrumentation

All three types of dual mobility cups (cementless press-fit, tripod, cemented) use the same Hip’n go instrumentation set. Two impaction systems are available.

This instrumentation can be used with every surgical approach, including anterior, posterior and minimally invasive.

Publications

- Over ten‑year follow‑up results of a prospective and consecutive series of primary total hip arthroplasty with an original cementless total hip prosthesis

Claude Schwartz, Christophe Bussiere, François Chalencon, Franck Cladiere, Philippe Forgeois, Christophe Fornasieri

Received: 28 November 2023 / Accepted: 12 December 2023 / Published online: 28 December 2023

© The Author(s) 2023

Downloads and media

Download documentation

Download surgical technique

Interested in this product?